Warshada Saliida Leaching Solvent: Nooca Loop Soosaarayaasha

Sharaxaada Alaabta

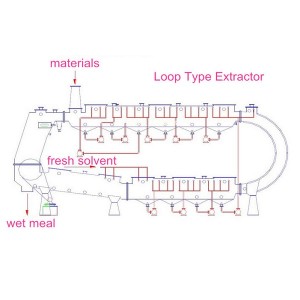

Kala-saarista dareeraha waa hab lagu soo saaro saliidda alaabta saliidda qaada iyadoo la adeegsanayo dareeraha, dareeraha caadiga ah waa hexane.Warshada soo saarista saliidda khudradda waa qayb ka mid ah warshadaynta saliidda khudradda taas oo loogu talagalay inay si toos ah saliid uga soo saarto abuurka saliidda oo ay ku jiraan wax ka yar 20% saliid, sida soyga, ka dib marka ay dhalaalto.Ama waxa ay saliid ka soo saartaa keegga iniinaha ah ee hore loo riixay ama si buuxda loo tuujiyey oo ay ku jiraan in ka badan 20% saliid, sida gabbaldayaha, lawska, iniinaha suufka ah iyo agabyo kale duwan oo kala duwan.

Inta lagu jiro tignoolajiyada leaching, geeddi-socodka leaching waa qaybta ugu muhiimsan ee tiknoolajiyada oo dhan, iyada oo aan loo eegin in ay si toos ah uga soo baxdo flacks, leaching of keega horay loo riixay ama leaching ee walxaha bararsan, taas oo mabda'a shaqadu ay isku mid yihiin, laakiin daawaynta ka hor ee maaddadu way ka duwan tahay, sidaas darteed waxaa jira qaar ka mid ah farqiga u dhexeeya xaaladda processing iyo xulashada qalabka laga soo bilaabo walxo kala duwan.

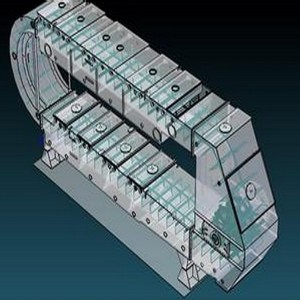

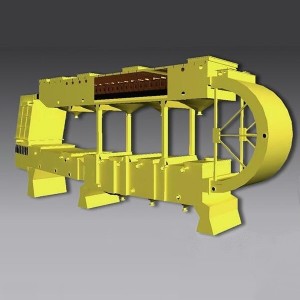

Soosaarayaasha nooca loop-ka ah ayaa ku habboon warshadda saliidda weyn si loo soo saaro, waxay qabataa nidaamka wadista silsiladda, waa mid ka mid ah habka soo saarista suurtagalka ah ee laga heli karo warshadda soo saarista dareeraha.Qaab-dhismeedka cusub ee loop-ku wuxuu xaqiijiyaa isticmaalka tamarta yar, dayactirka yar, wuxuuna yareeyaa buuqa.Xawaaraha wareega ee soosaariyaha nooca loop-ga ah si toos ah ayaa loo hagaajin karaa iyadoo loo eegayo tirada miraha saliida ee soo galaya si loo hubiyo in heerka qashinku yahay mid deggan.Tani waxay gacan ka geysan doontaa in ay abuurto cadaadis-negative-yar oo soo saarayaasha si looga hortago baxsashada gaaska dareeraha ah.Waxa intaa ka sii badan, sifadeeda ugu weyni waa abuurka saliidda ee qaybta foorarsiga si ay u rogto substratum, waxay ka dhigaysaa soo saarista saliidda mid si fiican isku mid ah, lakab gacmeed, cunto qoyan oo leh maaddo dareere ah oo yar, qadarka saliidda haraaga ah oo ka yar 1%.

Astaamaha soosaarayaasha nooca loop

1. Soosaarayaasha nooca loop wuxuu qaataa gudbinta silsiladda, nooc cusub oo qaab dhismeedka wareeg ah oo gaar ah, oo ku qalabaysan matoorka inta jeer ee la xakameeyo, isticmaalka tamarta yar, xawaaraha wareega hooseeya, socodka xasilloon oo aan buuq lahayn.

2. Nidaamka quudinta wuxuu si toos ah u hagaajin karaa xawaaraha socodka matoorka muhiimka ah iyadoo loo eegayo walxo kala duwan iyo qaddarka si loo ilaaliyo heerka walxaha qaarkood ee haanta kaydinta.Waxay ku habboon tahay samaynta cadaadiska micro-negative ee gudaha soosaariyaha si looga hortago daadinta dareeraha.

3. Wareegga saliidda ee Miscella ee horumarsan ayaa waxtar u leh si loo dhimo tirada gelitaanka dareeraha cusub, hoos u dhigida waxa ku jira saliidda hadhaaga ah ee cuntada, oo ay kordhiso fiirsashada Miscella, oo hoos u dhigto qaddarka uumi-baxa si loo gaaro ujeedada badbaadinta tamarta.

4. Lakabka walxaha soo saaruhu waxa loo qaabeeyey sidii hoose oo wuxuu isticmaalaa leaching percolation.Alaabta waa lagu wareejin doonaa qaybta foorarsiga si loo yareeyo dhinaca indho la'aanta ee dheecaanka.Si kastaba ha ahaatee, xaaladaha laxaadka muhiimka ah ee kala duwan ayaa sarreeya, dabarrada si wax ku ool ah ayaa loo tuuraa ka hor inta aan la gelin nidaamka uumiga.

5. Waxay qaadataa cadaadis taban oo buuxa oo uumi baxayo nidaamka uumi-baxa, oo leh waxtarka isticmaalka kulaylka oo sarreeya waxayna gacan ka geysataa hagaajinta tayada saliidda leaked.

6. Waxay qaadataa tignoolajiyada cadaadiska gebi ahaanba taban ee nidaamka isku-xidhka, oo leh waxtarka wareejinta kulaylka sare.

7. Koofiyeeriyaha birta ah ee toosan ee isku dhafan waxaa lagu isticmaalaa heerka soo kabashada dareeraha sare.Meel yar oo la degan yahay oo loogu talagalay kondenseriyaha caawinta si loo badbaadiyo maalgashiga mashruuca.

8. Habka aqoon-is-weydaarsiga waxaa lagu xakameyn karaa kombuyuutar, oo ay ku jiraan heerkulka, cadaadiska, heerka dareeraha iyo qulqulka uumiga, iwm. iyada oo loo marayo database-ku-xidhan.Golaha kontaroolku wuxuu qaataa kontaroolada software-ka, kormeeraha shaashadda weyn, noocyada xogta, warbixinta iyo daabacaadda u dhiganta, si isku mid ah loogu soo bandhigo nidaamka kontoroolka fogaanta, si loo baadho ogaanshaha qaladka iyo u falanqeynta fog iyo fogaanta fog, si loo caddeeyo tignoolajiyada waqtiga iyo waxtarka leh. taageero.

9. Qaado paroline ka soo kabashada dareeraha gaaska hawo-mareenka, gaaska hawo-mareenka waxa ku jira dareere yar.

10. Qaabka aqoon-is-weydaarsigu waa mid macquul ah, xarrago leh oo deeqsinimo leh.

| Qaabka | Awoodda (t/d) | Awood (kw) | Codsiga ugu muhiimsan | Calaamadee |

| YHJ100 | 80 ~ 120 | 4 | U isticmaal soo saarista saliidda miraha saliidda ee kala duwan | Gaar ahaan waxay ku habboon tahay miraha saliidda leh ee wanaagsan sida soybean

|

| YHJ150 | 140 ~ 160 | 5.5 | ||

| YHJ200 | 180 ~ 220 | 7.5 | ||

| YHJ300 | 280 ~ 320 | 11 | ||

| YHJ400 | 380 ~ 420 | 15 | ||

| YHJ500 | 480 ~ 520 | 15 |